|

The kit comes with

two brand new 280mm discs, marked left and right, 4 x 40mm long cap head

screws, 4 x 50mm long cap head screws, 4 x plain washers, 4 x taper washers,

2 x calliper adapter brackets, 2 x disc centring rings.

Interesting things

to add to your shopping list:

- new brake pads (new discs require new pads)

- 4 x screw to fix the discs (as the original part could get damaged).

|

|

Go ahead with jacking

up the front of the car and securing its position with a set of axle stands.

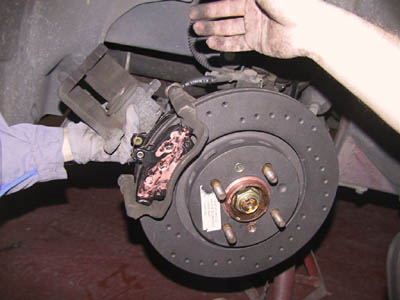

The picture at the

left shows the brake disc, brake calliper, both mounted on the wheel hub.

The orange marks are just grease, so it looks like this disc will come

of easy.

|

|

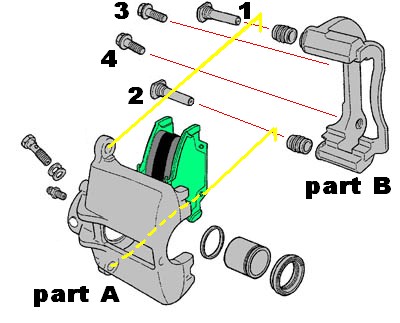

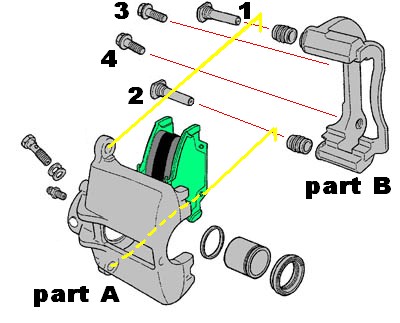

Remove part A (see

picture at the left) from the brake calliper by undoing bolts 1 and 2

(using a socket spanner). This action is followed by removing the 'old'

brake pads.

Remove the other part

of the brake calliper (part B) by unscrewing bolts 3 and 4. Don't disconnect

the hydraulics of the calliper, but place it in a position that is most

comfortable for the hydraulic piping. Use a small rope or cable wrap to

secure its position. The last thing you want is the situation where the

brake calliper drops and the hydraulics get disconnected or damaged.

|

|

Next step: use an impact

screwdriver and a proper bit to loosen up the screws of the discs. Two screws

per disc. |

|

Use some Locktight

(sp?, a thread-locking compound) on the bolts which will secure the bracket

to the hub (the 40mm once).

The tapered washers

should be fitted so the taper clears the radius in the corner of the calliper

bracket.

Fit the calliper bracket with the two tapered spaced washers in between

the hub and the plain washer under the head of the cap head screw.

|

|

|

|

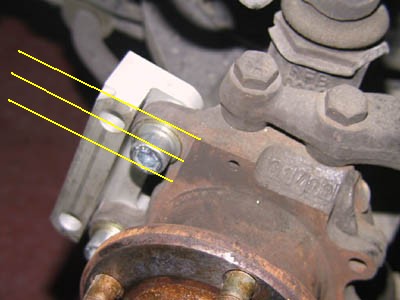

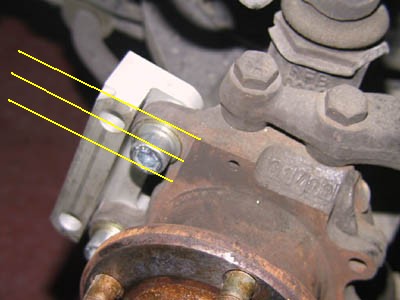

The bracket and washers

are fitted in this way that the surface of the hub where the bolt has its

hole and the surface of the bracket are in the same plane (as indicated

by the yellow lines on the picture at the left). It needs to be in this

way, as the calliper just needs to move in one direction (out of the center). |

|

Place the centring

rings with the chamfer to the inside (or with the flat side to the outside,

which makes it easy to use a small hammer to bring it in its final position.

Mount the new disc

onto the hub and secure it with the two retaining screws (it could be

usefull to use a set new ones).

|

|

Use some Locktight

on the 50mm bolts and use them to fixate the calliper part B to the bracket.

(picture left, below and below at the left) |

|

|

|

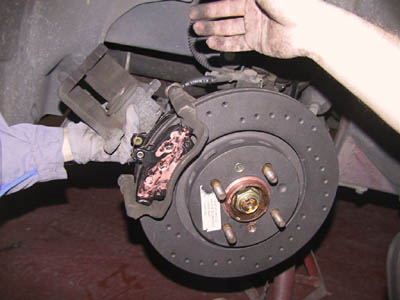

Use copper grease

or another more spoacialised product on the back (outside) of the new

pads and fit them at each side of the disc as shown in the picture at

the left.

Remove the other part

of the brake calliper from its secured position, and use a tool to press

the piston back in the calliper. There is no picture of this action, as

we didn't use the right tool for this, but it worked out fine (although

some serious power was required) . . .

|

|

Once the piston is

moved back again, slide the calliper over the pads and make sure it fits

properly.

Use the old bolts

to secure its position again.

|

|

Guess what, this brake

is finished, so put the wheel back on and start with the other side.

After finishing both

wheels and lowering the car, press the brake pedal 2 or 3 times to settle

the calliper piston before driving and avoid hard braking for the first

200 miles to allow the discs and pads to bed in.

|