The bracket with all the components, like it is provided by Brown & Gammons.

- A4 sized manual

- Bracket

- Oposite bracket piece

- 2 bolts

- 2 pairs of washers

- 2 nuts

M O D I F I C A T I O N S : BRAKES, Servo Mounting Bracket

A prefect lesson for a non-English speaking person to understand the word 'firmer'. Fitting the "servo mounting bracket support" makes the braking proces feel stronger, more solid. This bracket prevents the master brake cylinder to move while psuhing the brake pedal.

B

r o w n & G a m m o n s

"Offers a firmer brake pedal, as fitted to all Trophy race cars"

- RHD : BGF115 (£ 20.00 ex. VAT)*

- LHD : BGF115LHD (£ 20.00 ex. VAT)*

|

The bracket with all the components, like it is provided by Brown & Gammons. - A4 sized manual

|

F i t t i n g I n s t r u c t i o n s

NOTE: The pictures about fitting the bracket are different for a RHD car.

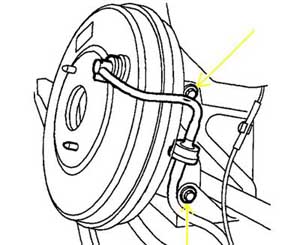

Remove the spare wheel and plastic shroud panel/cover under the front bonnet by using a 10mm socket on a ratchet and a Philips head screwdriver (yellow arrows on the picture bellow). The blue arrow indicates the position where the bracket will be mounted).

Remove the two bolts which keep the brake master cylinder in its place . . .

. . . and position the bracket in its place. Tighten the bolts again and have someone pushing against the master cylinder while tighting and marking the place on the paintwork where we need to drill or mark them by 'pre-drilling' with a smaller size.

Finally drill the two holes using a 8.5mm drill (better do this when the bracket is removed again). Drilling will be more difficult on a car without ABS (brake fluid pipes are routed different). Use some paint to cover the 'naked' metal and prevent it from corroding.

Relocate the bracket and insert the bolts through the bracket into the bulkhead. Find yourself someone who wants to crowl into the bulkhead (IMO the best position is: your back onto a a corner of the passengers seat, legs still outside the car, head where in a normal situation the passengers feet are located and a hand somewhere behind the central console, searching for the two bolts). Once the bolts are found, fit the smaller bracket, washers and nuts. Keep the nuts in their position, while the person at the front of the car tighten them.

Before refitting the shroud panel, tighten the bolts further on, in that way that (better seen from the top) the space between washer, bolt, bracket and master cylinder is gone.

.

.

This may require you to find a suitable position ;o) ... the reason why it's easier to remove the spare wheel ;o)

Thanks flies to Bruno V. who has done the largest part of this job.

* prices as quoted in December 2003